Contact Us: 020-31125660 Fax: 020-23889671

Wecome to Guangdong Eacoon Energy Technology Stock Co.,Ltd. website

PRODUCTS |

Non-standard Waste Power Generation Industry

As an inevitable product of urban metabolism, domestic refuse, if not properly handled, will bring obvious and potential long-term harm to human survival and development. How to deal with domestic waste effectively and environmentally is an important topic in the world environmental protection industry. Eacoon began to pay attention to and participate in the municipal solid waste incineration power generation project in 2006. In combination with the world's advanced technology, it has cooperated with Jiangxi Jianglian. After several years of efforts, we have won six projects of waste heat boiler for municipal solid waste incineration, with a daily total capacity of 6650 tons. In 2012, the company reached strategic cooperation with the world-renowned waste incineration power generation enterprise Stefford Group, Switzerland, to establish a joint venture waste incineration power generation equipment production base in Guangzhou, with an investment of 300 million yuan. Since its inception in 1973, Stefford has been committed to the development of energy and environmental protection technology. The company has many inventions and patented technologies in the field of waste incineration and power generation. Its products are sold all over the world, and construction projects are all over the world. On the basis of water-cooled devices, Stefford has developed its own incineration system, which has become an international leader in the field of waste incineration and power generation technology. Based on the company's technological advantages and equipment manufacturing advantages, the Group plans to invest in six garbage incineration power generation projects nationwide in five years, with 10,000 tons of garbage disposal per day and 3 million degrees of power generation per day. The annual output value of the business sector is expected to reach 850 million yuan.

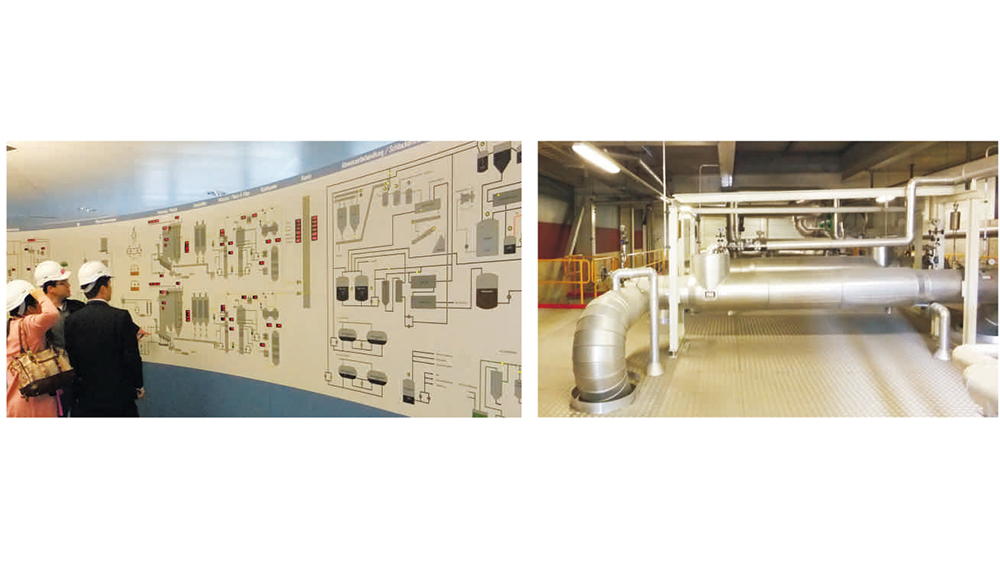

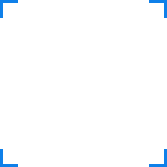

According to the characteristics of high moisture content, high non-combustible substance content and low calorific value of garbage in China, Eacoon and the advanced Swiss Stefford Group in the world jointly make use of the whole set of proprietary technologies of waste incineration water-cooled grate, flue gas purification system and landfill leachate treatment, and utilize the Group's waste heat boiler production and manufacturing technology, and adopt the international advanced DCS control system to ensure garbage incineration. The furnace maintains the best thermal radiation effect, dries the garbage quickly, optimizes the garbage incineration effect, effectively reduces the generation of dioxins in the process of garbage incineration, and combines with advanced flue gas purification technology to ensure that the flue gas emissions of garbage incineration power plants meet the international advanced standards.

Gaoan Eacoon Renewable Resources Thermal Power Generation Co., Ltd. Gaoan Eacoon Renewable Resources Thermal Power Generation Project in Jiangxi Province is located in Heling Town, Gao'an City, Jiangxi Province. The total design and construction scale of the project is 3*300 t/d, covering an area of 80 mu, the total installed capacity is 18 MW, and the total investment of the project is 330 million yuan. The first phase of 2*300 t/d has been put into operation in March 2018, with an annual disposal of 220,000 tons of domestic waste and an annual power generation capacity of 80 million kWh. The second phase of 300 t/d has reserved sites and is expected to be expanded by 2020.

Guangzhou Likeng Waste Incineration Power Plant The first and second phases of Likeng municipal solid waste incineration power plant in Guangzhou are key projects of municipal environmental protection projects. The plant uses safe and R incineration method to treat domestic waste, recycles heat energy and generates electricity with high efficiency and low cost, designs and constructs high standard requirements, and imports the most advanced technology from abroad for the key equipment such as waste incinerator, flue gas treatment and field control system, which really ignores the reduction, harmlessness and resource utilization of waste treatment. The first phase of the project can dispose of 1040 tons of garbage per day, with an average daily power consumption of about 360,000 kWh and annual power generation of about 130,000 kWh, which can supply 100,000 households with electricity. The second phase of the project will be completed and put into operation in 2011, with daily treatment of 2,000 tons of domestic waste.

North Zhongshan Group Waste Incineration Power Plant The garbage incineration power plant in the northern group garbage comprehensive treatment base of Zhongshan City is an important municipal environmental infrastructure built by the Zhongshan Municipal Government in combination with the strategic requirements of sustainable development such as urban construction, energy-filled structure and environmental pollution control. Its treatment scale is 1000 tons per day, the power generation capacity of energy recovery system is 24MW, and the annual power generation on the grid is about 100 million degrees. The project was completed and put into operation in 2008.

Guizhou Songtao Recycled Resources Thermal Power Plant In November 2012, the Group signed a contract with Songtao Miao Autonomous County, Guizhou Province, to invest in the construction of regenerative resources thermal power plant in Songtao Miao Autonomous County, Guizhou Province. The project invests nearly 300 million yuan. The project is divided into two phases. Two production lines are planned to be built to deal with 300 tons of domestic waste per day. Mechanical water-cooled furnace exhaust technology, flue gas purification system technology, landfill leachate treatment technology and DCS central control technology are adopted. System technology, supporting two 6 MW generating units, the second phase will be completed when the annual disposal of domestic waste up to 200,000 tons of scale, annual power generation will reach 55 million degrees. At present, the project has entered the preparations for the previous work. |